All modern vehicles are equipped with an onboard computer diagnostic system (OBDII) that constantly monitors your vehicle’s major operating systems and most importantly the power-train (engine and transmission). The main purpose of monitoring these systems is to insure that the vehicle is operating at top efficiency with the lowest possible emissions. As fuel economy and emission control has become increasingly important and complex, your vehicle’s electronics systems need to constantly adjust and fine-tune various parameters according to driving conditions (such as vehicle load, temperature and air/fuel mix to name just a few). When the computer reads that any of these parameters do not fall within the acceptable range for operating the vehicle, your CHECK ENGINE LIGHT is lit to warn you that you may have a serious problem and to take your vehicle to a certified technician – such as your local AAMCO technician – to check the faults and restore it to manufacturer’s specifications.

All modern vehicles are equipped with an onboard computer diagnostic system (OBDII) that constantly monitors your vehicle’s major operating systems and most importantly the power-train (engine and transmission). The main purpose of monitoring these systems is to insure that the vehicle is operating at top efficiency with the lowest possible emissions. As fuel economy and emission control has become increasingly important and complex, your vehicle’s electronics systems need to constantly adjust and fine-tune various parameters according to driving conditions (such as vehicle load, temperature and air/fuel mix to name just a few). When the computer reads that any of these parameters do not fall within the acceptable range for operating the vehicle, your CHECK ENGINE LIGHT is lit to warn you that you may have a serious problem and to take your vehicle to a certified technician – such as your local AAMCO technician – to check the faults and restore it to manufacturer’s specifications.

What is the check?

Reading the codes from your car’s computer system is similar to a doctor measuring your blood pressure when you schedule a visit. High blood pressure doesn’t tell the doctor what is wrong with you it simply lets the doctor know there is something wrong and points him or her in the right direction to find out what it is. Just like the CHECK ENGINE LIGHT codes tell your AAMCO technician there is something wrong and points him or her in the right direction, too. If the code indicates a problem with your O2 (oxygen) sensor system, it doesn’t necessarily mean you need a new O2 sensor. Additional diagnostics pinpoints the exact cause of the “trouble” code so you don’t pay for parts or services you don’t need. Be wary of garages that read your code and tell you immediately that you need a major repair.

What does the CHECK ENGINE LIGHT usually mean?

What does the CHECK ENGINE LIGHT usually mean?

There are hundreds of codes that could trigger your CHECK ENGINE LIGHT for dozens of reasons each. Even the most common reasons can have many possible causes. Some top CHECK ENGINE LIGHT codes are:

- Problem with the Mass Air Flow (MAF) sensor or circuit. You may not notice any serious drivability problems, although there may be symptoms such as a general decrease in power or sluggishness. This could be caused by a simple connection problem of the sensor, a wiring connection may be bad or dirty or the Mass Air Flow sensor may be faulty.

- System Running Too Lean. An oxygen sensor detected a lean condition (too much oxygen in the exhaust). You may notice a lack of power, detonation (spark knock) and/or a hesitation/surge on acceleration which could be caused by a dirty Mass Air Flow sensor or air filter or a vacuum or exhaust leak in the system.

System Running Too Rich: The oxygen sensor detected a rich condition (or a too-high fuel to oxygen ratio). You may experience misfires with this condition. This condition can be caused by a dirty or faulty Mass Air Flow sensor, air filter, a blockage or restriction in the airstream, a fuel pressure, fuel injector or fuel delivery problem.

System Running Too Rich: The oxygen sensor detected a rich condition (or a too-high fuel to oxygen ratio). You may experience misfires with this condition. This condition can be caused by a dirty or faulty Mass Air Flow sensor, air filter, a blockage or restriction in the airstream, a fuel pressure, fuel injector or fuel delivery problem.- Cylinder Misfire: A P0300 series of codes indicates a random or multiple misfire in your engine. You may find your engine harder to start, the engine may stumble, idle rough and/or hesitate among other driveability symptoms. This could mean anything from faulty spark plugs or spark plug wires, a bad ignition coil, a vacuum or air leak, to a serious mechanic problem in your engine. This code is serious when flashing and can cause faulty catalytic converter(s).

- Knock Sensor Circuit Malfunction: Your vehicle’s computer constantly adjusts and retimes the engine so that it doesn’t produce harmful pre-ignition detonation or knock. With this malfunction you may notice drivability problems including, not surprisingly, knocks and a lack of power and hesitation. It could mean the knock sensor is faulty and needs to be replaced, that there is a wiring short/fault in the knock sensor circuit or that you have other problems that the knock sensor cannot control.

- Insufficient EGR (Exhaust Gas Recirculation) Flow: Your vehicle recirculates exhaust back into the combustion chamber to better achieve optimal combustion chamber temperature and to reduce NOX (a harmful greenhouse gas). This light triggers when there is insufficient EGR flow in the combustion chamber and you may notice a pinging when the vehicle is at higher speeds. There may also be other symptoms. It could be a faulty sensor, valve or blockage in the EGR (tube) from a carbon buildup.

- Catalyst System Efficiency below Threshold : The oxygen sensor after the catalytic converter is detecting that the converter is not working as efficiently as it should be (according to specs). You will likely not even notice any drivability problems though your vehicle may have anything from an oxygen sensor not reading (functioning) properly to a damaged exhaust manifold or a bad catalytic converter.

These are just a few of the hundreds of codes, causes and symptoms, each has multiple fixes.

What happens when I ignore the CHECK ENGINE LIGHT?

There are two kinds of CHECK ENGINE LIGHT alerts. A non-flashing but lit CHECK ENGINE LIGHT, is usually a less severe problem that shouldn’t cause immediate problems but needs to be checked as soon as possible. Also, a flashing and illuminated CHECK ENGINE LIGHT means your vehicle senses a critical system error (such as a major cylinder misfire ) and you need immediate attention before potentially breaking down and possibly damaging other critical and expensive parts. In this case, continuing to drive can lead to further damage rather quickly or can leave you stranded.

Driving the vehicle with a non-flashing generic code will almost certainly cause an increase in emissions and a decrease in fuel economy-which can be robbing you of up to 20% fuel efficiency at each fill-up. Looking at it a different way, based on $3 per gallon, typically you could be wasting $7.50 per fill-up or upwards of $300 per year.

As quite a few of the systems work interdependent of one another, an error in one system can affect the operation in another. EVAP codes (vacuum related), EGR, temperature, speed sensors, etc. can all have an effect on how the transmission acts and shifts or how the engine performs or the cooling fans turn on, etc. Ignoring these important warnings may create other critical issues.

Finally, if you live in one of the areas that require it, you certainly cannot pass state mandated Emission/Smog inspection with your CHECK ENGINE LIGHT

Cleans your engine

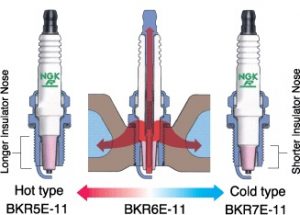

Cleans your engine Surface area and/or length of the insulator nose

Surface area and/or length of the insulator nose