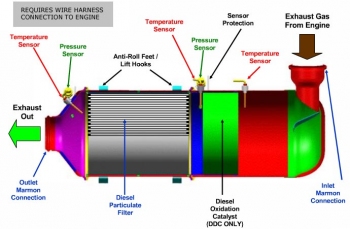

To prevent the DPF from becoming dirty or clogged, which consequently impairs its function, it must be regenerated regularly by a process of burning off the soot particles that have accumulated inside the filter.

Soot particles are burned off steadily without the intervention of the ECU. This is achieved at standard highway speeds (3000 r/min). The temperature of the exhaust gas will reach around 660°F – 930°F.

In cases of predominantly urban use, the temperature of the exhaust gas fails to reach sufficient temperatures to achieve passive regeneration. Consequently, soot particles are not eliminated and instead accumulate inside the filter. When a clogging threshold is reached (18 grams), the engine’s computer will trigger active regeneration.

The degree of carbon accumulation inside the DPF is calculated using two models programmed within the ECU:

– A model based on the driver profile, which calculates saturation according to a specific pattern of signals coming from the temperature transmitters of the exhaust gas as well as the oxygen sensor.

– A model based on the flow resistance of the DPF, which calculates saturation according to signals reassembled by the differential pressure sensor, temperature transmitters, and air flow meter, which then all inform the ECU of the degree of saturation inside the DPF.

The pressure sensor measures the difference in pressure between the inlet and the

outlet of the DPF, the difference in pressure corresponding to the degree of saturation

inside the filter. The more the filter is clogged, the higher the voltage (in volts)

transmitted by the sensor to the ECU. At a specific voltage, corresponding to the

quantity of carbon particles (grams), the ECU will activate forced regeneration of the

DPF by raising the temperature of the exhaust gas to 1020°F/1200°F.

To achieve this increase in temperature, the ECU will perform several actions:

– Regulating the flow of air through the electronic throttle control (ETC).

– Deactivating the EGR valve from recycling exhaust gases in order to increase the combustion temperature.

– Triggering a first post-injection following the principal injection in order to increase the combustion temperature.

– Triggering a second post-injection, causing the unburned fuel to evaporate inside the combustion chamber. The unburned hydrocarbons are oxidized by the vapor inside the catalyst converter. The heat generated during this stage can reach temperatures of 1140°F inside the DPF.

– The transmitter signal, located upstream of the DPF, is used by the ECU to determine the amount of fuel to be injected in the second post-injection.

In this case, active regeneration is blocked by the ECU in order to prevent degradation of the filter. At this point, the DPF must be regenerated in a garage by experienced technicians.

In this case, active regeneration is blocked by the ECU in order to prevent degradation of the filter. At this point, the DPF must be regenerated in a garage by experienced technicians.